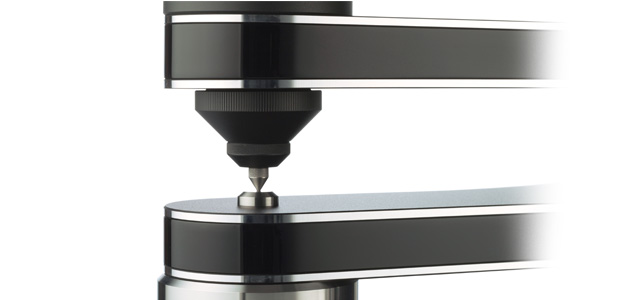

Two opposing magnetic fields are perfectly aligned one on top of the other, thereby rejecting each other. The magnetic fields are completely shielded from the outside through the careful application of very sophisticated materials. A high precision ceramic vertical shaft fits perfectly into a bronze bearing. This perfect fit is essential and can only be achieved through the highest precision hand polishing.

High-performance synthetic oil is used for lubrication. The combination of these carefully selected components produces the effect of the turntable platter effectively floating on an air cushion, rather than on a ball bearing or bearing point.

The result of this technology? One of the lowest levels of friction in turntable bearing design, previously unreached rumble measurements and an unbeatable new standard in speed accuracy.